Footprint

Reuse is a profitable strategy for achieving sustainability objectives. Producing flowerbulbs eco-friendly is paramount naturally, but switching to sustainable packaging will certainly be obvious as well and relatively easy to implement.

The use of plastic packaging is an emotionally charged topic. Governments are taking measures to reduce single-use plastic. In the minds of many, plastic is linked to pollution of the environment. However, plastic crates rarely end up in the sea.

Production

The use of plastic transport packaging (single-use or multiple use) has an impact on climate change. Plastic crates are made by injection molding of HDPE. The raw material consists of pellets from recycling, which are liquefied by heating upto 130 °C . The liquid material is injected into the mold under high pressure and then cooled until the plastic solidifies. This process requires a lot of energy (+ emissions) and water, which is used as sustainably as possible by the manufacturer. The plastic product that results from this is robust and durable and can be used for a long time. So far, single-use and multiple-use plastic crates are equivalent in their environmental impact. Then the differences arise.

Environmental impact in the supply chain

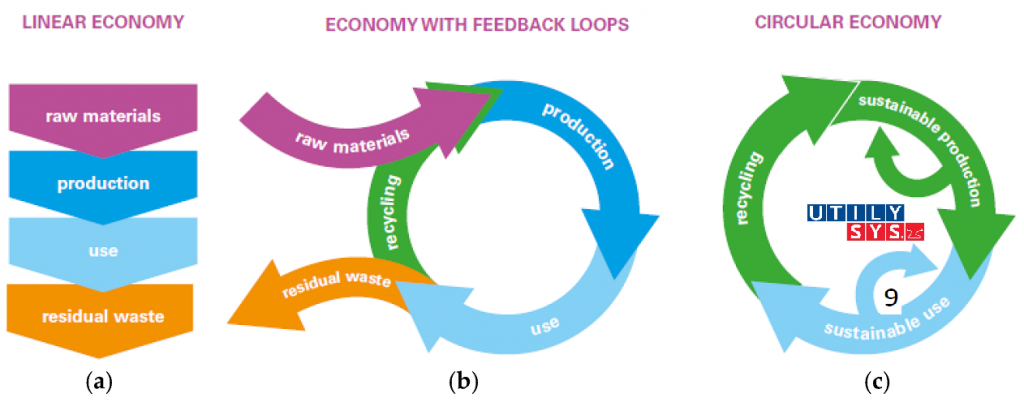

Folding crates are transported to the packing location in 20% of the transport volume. There they are filled like other crates and sent to their destination. In the subsequent journey, the crates do not come from the factory but are reused after return transport and cleaning. This also requires energy (+ emissions) and water. Recycling of plastic is unnecessary for as long as possible. On balance, this reuse yields a considerable saving in energy, emissions and water compared to recycling disposable plastic crates. After many years of use, a high-quality recyclate remains, while the raw material would have degenerated if the crates would have been used once and then recycled year after year.

Waste prevention

In the waste hierarchy of plastic Reuse has priority over Recycling. Reduce, Reuse, Repair, Recycle prevent crates from ending up in waste prematurely for landfill or incineration. The chance that crates unintentionally end up in waste is much smaller within a returnable crates system, because returning empty crates means receipt of the depostit. The crate-owner is well prepared to sort out plastic crates that have become unusable after a service period and dispose of them through a recycling company.